When it comes to home improvement and construction projects, the choice of tools can significantly impact the quality and efficiency of your work. Among these tools, the Glass Hole Saw is a critical component for creating precise holes in various glass materials, allowing for seamless installations and repairs. According to a recent industry report by ResearchAndMarkets, the global diamond drill bit market, which includes glass hole saws, is expected to grow at a CAGR of 5.1% from 2021 to 2026, reflecting an increasing demand for specialized tools in both professional and DIY sectors. Understanding the different types of glass hole saws, their applications, and selection criteria is essential for achieving optimal results. This guide will provide you with the insights needed to make an informed decision when choosing the perfect glass hole saw for your projects.

When it comes to selecting the right glass hole saw for your projects, understanding the different types available on the market is crucial.

Glass hole saws are primarily designed for creating clean, precise holes in various types of glass, whether for DIY home improvements or crafting.

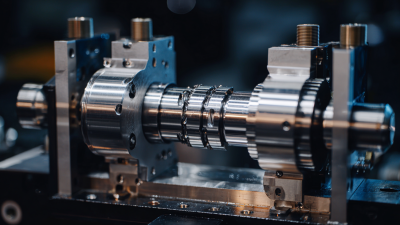

These tools typically feature hardened tips made from either tungsten carbide or diamond-coated materials, ensuring durability and efficiency in drilling through tough glass surfaces.

Glass hole saws are primarily designed for creating clean, precise holes in various types of glass, whether for DIY home improvements or crafting.

These tools typically feature hardened tips made from either tungsten carbide or diamond-coated materials, ensuring durability and efficiency in drilling through tough glass surfaces.

Each type of glass hole saw caters to specific needs. For example, diamond-coated saws offer superior finishing and are ideal for delicate glass projects due to their ability to minimize chipping.

On the other hand, tungsten carbide options are more suited for bulkier tasks where speed is essential.

By knowing the characteristics of each type, you can make informed choices that will yield the best results for your creative projects.

When selecting a glass hole saw for your projects, there are several key features to consider that will ensure you achieve optimal results. Firstly, the size of the hole saw is critical. Depending on the specific application, you’ll need to select the right diameter. Using a saw that’s too large or too small can lead to improper cuts, resulting in wasted materials and additional effort.

Tip: Always measure the exact diameter needed before purchasing your hole saw to avoid costly mistakes.

Another essential feature is the construction material of the hole saw. For glass, carbide or diamond-tipped hole saws are highly recommended due to their durability and cutting efficiency. These materials can better handle the hardness of glass, reducing the risk of cracks and ensuring a cleaner finish.

Tip: Invest in a high-quality hole saw to make your project easier and more effective; it may cost a bit more upfront but will save you time and resources in the long run.

Additionally, consider the design of the hole saw. A saw with a good cutting edge and a smooth outer surface will enhance your control during the drilling process. Ensuring compatibility with your power tool is equally important, as this will affect the efficiency of your work.

Tip: Test the hole saw on a scrap piece of glass before moving to your final project to ensure it performs as expected.

| Feature | Description | Recommended Size (inches) | Material Compatibility | Typical Use Cases |

|---|---|---|---|---|

| Pilot Bit | A central drill bit that helps guide the hole saw for accurate drilling. | Varies (1/4", 1/8") | Glass, wood | Installation of fixtures, light switches |

| Tooth Design | Type of tooth can affect the speed and smoothness of the cut. | 2"-6" | Acrylic, glass | Creating hole for cables, plumbing |

| Coating | Special coatings prevent overheating and increase the lifespan of the hole saw. | 1"-8" | Glass, tile | Bathroom installation, art projects |

| Arbor Size | The size of the arbor that fits in your drill. | 3/8", 1/2" | All types | Handyman tasks, DIY projects |

| Cutting Depth | Maximum thickness the hole saw can cut through. | 1/4"-2" | Glass, ceramic | Special features installation |

When tackling a project involving glass, choosing the right glass hole saw is crucial for ensuring safety and effectiveness. A step-by-step approach can guide you through the selection and usage process. Start by assessing the materials you’ll be working with and identifying the size of the hole you need. Various saw types are available, including diamond-tipped and carbide-tipped options, each suited for different glass thicknesses. It’s essential to select a drill bit that matches the specific requirements of your project to avoid damage to the glass and ensure precise results.

Once you've chosen the appropriate glass hole saw, proper usage techniques come into play. Always wear safety goggles and gloves to protect yourself from shards and debris. Begin drilling at a low speed to prevent the glass from cracking, applying steady, even pressure as you work. To enhance stability, consider using a wet drilling method, which not only cools the bit but also reduces dust. By following these steps and prioritizing safety, you can effectively use a glass hole saw for flawless results in your projects.

When it comes to selecting a high-quality glass hole saw, choosing from top brands is essential for ensuring precision and durability in your projects. According to a recent market report from Grand View Research, the global power tools market, which includes specialty saws, is projected to reach $39.9 billion by 2027, highlighting the increasing demand for reliable and efficient tools. Brands such as Bosch, Diablo, and Ryobi have emerged as leaders in this niche, consistently receiving positive feedback for their performance in cutting through various glass types.

Bosch, known for its innovative technology, offers a diamond-coated hole saw designed specifically for glass, providing smoother cuts and extended tool life. A study by the Tool Manufacturers Association found that tools featuring advanced coating techniques can reduce wear by up to 30%, which enhances overall efficiency. Meanwhile, Diablo's carbide-tipped glass hole saws are praised for their ability to handle both tempered and non-tempered glass, making them versatile choices for any DIY enthusiast or professional. Understanding these options and the respective benefits of leading brands can significantly improve your project outcomes.

When selecting a glass hole saw for your projects, avoiding common mistakes can significantly enhance your experience and outcomes. One prevalent error is neglecting to account for the type of glass being used. According to a 2021 report by the Glass Association, different glass types require specific saws to achieve clean cuts. For example, tempered glass demands diamond-tipped hole saws due to its strength, while standard glass is more forgiving and can be cut with carbide-tipped versions.

Another frequent pitfall is overlooking the importance of size and depth. Selecting a hole saw that is either too large or too small for your desired hole can lead to wasted materials and frustrated efforts. A survey by the DIY Tools Institute found that 40% of hobbyists reported poor project results due to improper sizing. Always measure your requirements carefully before making a purchase.

**Tips:** When in doubt, consult manufacturer guidelines to ensure compatibility with your glass type. Furthermore, consider investing in a saw with adjustable depth settings, as this versatility can save you time and materials across a range of projects. Lastly, always test on scrap material before committing to your final piece to ensure your chosen tool meets your needs effectively.