In the evolving landscape of manufacturing, the demand for precision tools such as the hole saw for metal has surged significantly. According to recent industry reports, the global metal cutting tools market is projected to reach $9.69 billion by 2026, growing at a CAGR of 5.2% from 2021 to 2026. This growth is driven by advancements in manufacturing technologies and the rising need for efficiency across various sectors, including automotive, aerospace, and construction.

China has emerged as a pivotal player in this space, renowned for its superior quality manufacturing and competitive pricing. As global partners increasingly tap into Chinese innovations, the pursuit of the best hole saw for metal becomes not only a strategic choice but also a testament to the nation's craftsmanship that continuously meets international standards. With a vast export network, Chinese manufacturers are set to fulfill the growing global demand, thus solidifying their position in the worldwide market.

China has emerged as a pivotal player in this space, renowned for its superior quality manufacturing and competitive pricing. As global partners increasingly tap into Chinese innovations, the pursuit of the best hole saw for metal becomes not only a strategic choice but also a testament to the nation's craftsmanship that continuously meets international standards. With a vast export network, Chinese manufacturers are set to fulfill the growing global demand, thus solidifying their position in the worldwide market.

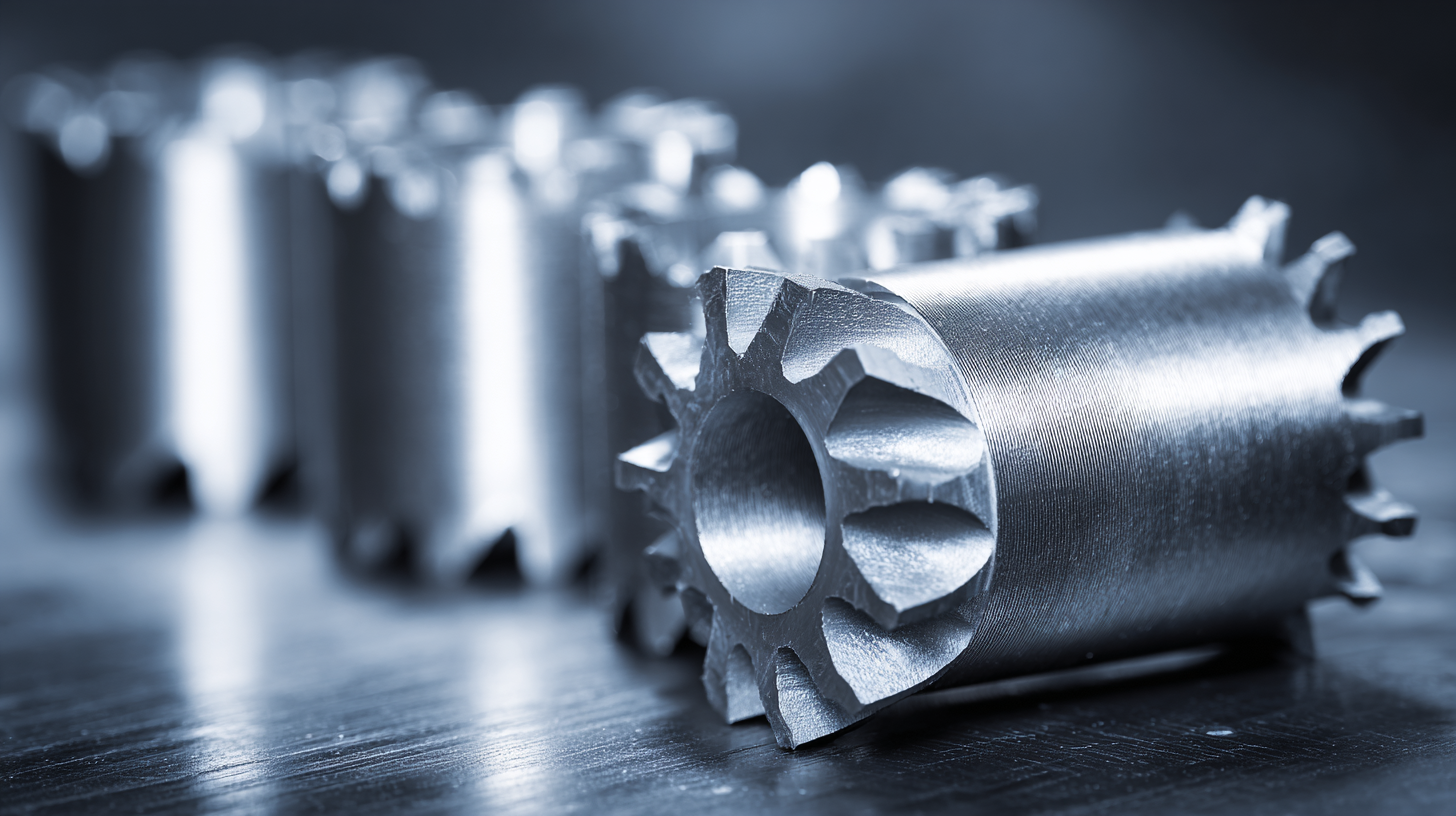

When selecting a hole saw for metal cutting applications, understanding the key specifications is essential for achieving high-quality results. One of the most critical factors to consider is the material of the hole saw itself. Bi-metal hole saws, typically made from a combination of high-speed steel and carbon steel, offer durability and flexibility, making them ideal for cutting various metals, including aluminum and mild steel. Additionally, the tooth design and pitch are crucial; fewer teeth can lead to faster cutting, while more teeth provide a smoother finish, allowing you to choose based on your project’s requirements.

Another important specification is the diameter of the hole saw. Depending on the size of the holes being created, hole saws come in various diameters, typically ranging from 3/4 inch to several inches. It's also vital to ensure the saw's compatibility with your drill, particularly its arbor size. Lastly, consider the cutting depth; some applications may require deeper cuts that conventional hole saws cannot accommodate. Selecting the right hole saw by understanding these specifications will enhance your cutting efficiency and material quality, positioning you for success in your metalworking projects.

The hole saw industry is experiencing significant growth, particularly in China, driven by rising demand for precision tools in various sectors, including construction and manufacturing. As reported in the Global Private Markets Report 2025, private equity trends highlight increased investment in manufacturing technologies, with companies seeking high-quality products that deliver reliability and performance. The expansion of manufacturing capabilities in China positions it as a leading player in the global market for hole saws, where quality and innovation are paramount.

Market analysis suggests that the global hole saw market is expected to grow significantly, with annual growth rates projected at over 6% through the next five years. This growth reflects not only the rising demand in developing economies but also advancements in material technology and design. As companies in China enhance their manufacturing processes, they are likely to produce hole saws that offer increased durability and efficiency, catering to the evolving needs of a diverse customer base. In a rapidly changing market landscape, China's commitment to quality and innovation makes it a crucial global partner for those seeking the best in metal hole saw solutions.

When selecting a hole saw for metal fabrication, performance metrics are crucial in determining the right tool for the job. According to a recent industry report by Market Research Future, the global hole saw market is projected to grow at a CAGR of 6.2% from 2022 to 2028, driven by increases in manufacturing and construction activities. Performance data reveals that high-speed steel (HSS) hole saws outperform their bi-metal counterparts in terms of heat resistance and longevity, with some models lasting up to 50% longer in continuous-use applications.

Moreover, a survey conducted by the Cutting Tool Engineers Association indicates that precision and cut quality are paramount for 75% of fabricators. The report shows that premium hole saws equipped with advanced teeth design can achieve cutting speeds of 50% faster while maintaining high accuracy, minimizing the risk of burrs and improving overall finish. By leveraging China's robust manufacturing capabilities, businesses can access these high-performance tools that align with operational demands, ensuring efficiency and quality in metalworking projects.

| Hole Saw Size (inches) | Material | Teeth Count | Cutting Depth (inches) | Average Cutting Speed (RPM) | Durability (Cuts) |

|---|---|---|---|---|---|

| 1.5 | HSS | 12 | 1.8 | 1500 | 50 |

| 2.0 | Bi-Metal | 14 | 2.0 | 1300 | 100 |

| 2.5 | Cobalt | 10 | 2.5 | 1200 | 75 |

| 3.0 | HSS | 16 | 3.0 | 1100 | 60 |

| 3.5 | Bi-Metal | 18 | 3.5 | 1000 | 50 |

When it comes to manufacturing high-quality hole saws for metal, China has established itself as a leader in the industry, thanks to its rigorous quality control processes. Ensuring optimal durability and precision starts right from the selection of raw materials. Chinese manufacturers pay meticulous attention to sourcing the best metals, as the composition directly influences the strength and longevity of the hole saws. Through advanced metallurgy and material testing, manufacturers can guarantee that their products meet international standards and provide reliable performance in various applications.

Moreover, quality control doesn’t stop with raw materials; it extends throughout the entire production process. Implementing strict inspection protocols at every stage helps in identifying potential flaws early on. From designing the geometry of the saw teeth to the final finishing touches, every detail is scrutinized to ensure excellence. Manufacturers employ skilled technicians and utilize state-of-the-art machinery, which together enhance both precision and efficiency. As a result, customers can trust that the hole saws produced will perform optimally, even in the most demanding environments. By partnering with China's quality manufacturers, businesses can invest in tools that not only meet but exceed their operational needs.

When it comes to sourcing hole saws for metalworking, China stands out as a leader in quality and cost-effectiveness. The country’s robust manufacturing capabilities enable it to produce a wide range of tools that meet global standards. A comparative analysis reveals that opting for hole saws from China can significantly reduce costs without compromising on performance. Chinese manufacturers often leverage advanced technology and efficient production processes, allowing them to offer competitive prices that benefit businesses worldwide.

In contrast, sourcing hole saws from other regions may lead to higher expenses, particularly when considering factors such as import duties, labor costs, and limited production scale. For instance, many Western brands charge a premium for their products, attributing it to higher production and operational costs. However, when businesses evaluate the total cost of ownership, including durability and frequency of replacement, Chinese hole saws often emerge as a more economical choice. The price-savings, coupled with consistent quality, make China an invaluable partner in the global market for metalworking tools.